Wire cloth terminology according to iso 9044

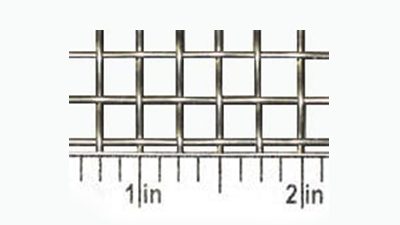

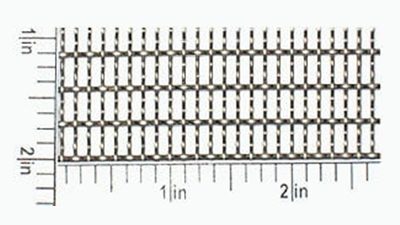

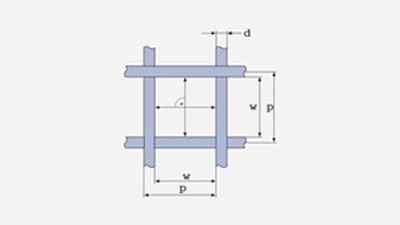

Aperture Width (W) is the distance between two adjacent warp or weft wires, measured in the projected plane at the mid positions.

Warp: All wires running lengthwise of the cloth as woven.

Weft: All wires running across the cloth as woven.

Wire diameter (d) is the diameter of the wire in the woven cloth (the wire diameter may be altered slightly during the weaving process.)

Pitch (p) is the distance between the middle point of the two adjacent wires or the sum of the aperture width (w) and wire diameter (d).

The number of apertures per unit length (n) is the number of apertures counted in a row one behind the other for a given unit length. The unit length may be 1cm, 1dm, 1in, or any other unit of length; however, the number of apertures with a length of 25.4mm is designated as “Mesh”.

Mesh = number of apertures perinch = 25.4mm :

pn/cm = number of apertures per cm = 10 : p

pn/cm2 = number of apertures per cm2 = (10 : p)2

Open screening area (A°) is the percentage of the area of all apertures in the total screening surface, or the ratio of the square of the nominal aperture width (w) to the square of the nominal pitch p(=w+d), rounded to a full percentage value.

A° = 100.(w : p)2

Type of weave is the way in which the warp and weft wires cross each other.

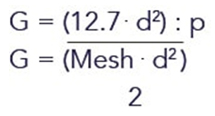

Weight (G) of the steel wire cloth screen section in kg per m2 :

The actual value can be calculated using the following equation:

TYPES OF WEAVE

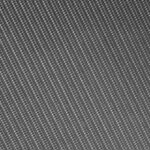

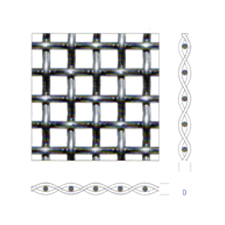

Plain Weave

The plain weave wire mesh is also called as square weave & it’s the most commonly used weave. Each weft wire passes alternatively over and under each warp wire, and vice versa. The warp and weft wire diameters are usually the same.

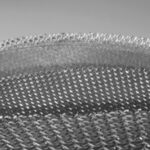

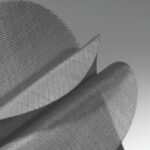

Plain Dutch Weave

The Plain Dutch weave is a type of weave with larger warp wires than the weft wires. The weave is made up of a limited number of warp wires interwoven with the maximum number of weft wires, thereby producing a stable and strong cloth. The warp wires in this weave type are always stronger than the weft wires. The so-called “Zero-Mesh” is created by positioning the weft wires as closely as possible together. This weave type has a high filtration level and high-pressure resistance.

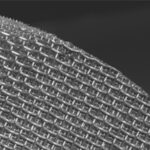

Twilled Dutch Weave

The Dutch twill weave is similar to the plain Dutch weave, except that the weave has a twill pattern and a double layer of weft threads. In Dutch Twilled Weave each of the warp and Shute wires are woven alternately over two or more successive Shute and warp wires, keeping a constant distance between adjacent susceptive. The mesh has a broad application tendency of supporting larger loads and finer filtrations.

STAINLESS STEEL AISI 304-L (LOW CARBON AND HIGH NICKEL)

Stainless steel is typically selected for applications where corrosion resistance is required in a wide range of environmental conditions. Typical stainless mesh materials include 17-7 PH® (UNS S17700), 316 (UNS S31600), and 304 (UNS S30400). By far, 304 & 304L are the most used stainless steel for most corrosion-resistant applications.

Stainless Steel 304L (Low carbon and high 8% nickel) has a higher resistance to heat and pressure that enables the pro-long life of filter mesh. As per International Standard ISO 4782, wire should have the following chemical composition.

| CHEMICAL COMPOSITION | %C | %Mn | %Si | %S | %P | %Ni | %Cr |

| Min | 8.00 | 18.00 | |||||

| Max | 0.03 | 2.00 | 1.00 | 0.030 | 0.045 | 12.00 | 20.00 |